Understanding Soda Blasting: A Comprehensive Guide

What is Soda Blasting?

Soda blasting is a modern, environmentally friendly cleaning and surface preparation technique. It uses sodium bicarbonate particles, commonly known as baking soda, as the blasting medium. This method is effective for removing contaminants from a variety of surfaces without causing damage. It is often used in industries ranging from automotive restoration to food processing equipment maintenance.

How Does Soda Blasting Work?

The process of soda blasting involves projecting sodium bicarbonate particles at high speeds using compressed air. These particles are soft enough to clean surfaces without scratching or harming them. As the particles impact the surface, they break down and create a gentle abrasive action that lifts away dirt, grease, and coatings. The result is a clean, smooth surface ready for repainting or other treatments.

One of the key advantages of soda blasting over traditional abrasive methods is its non-destructive nature. While sandblasting can be too harsh for delicate surfaces, soda blasting is much gentler, making it suitable for a wider range of applications.

Applications of Soda Blasting

Soda blasting is incredibly versatile and can be used in various situations. In the automotive industry, it is popular for paint stripping and rust removal on classic cars, as it preserves the integrity of the vehicle’s metalwork. In the food industry, soda blasting cleans processing equipment without the risk of contamination.

Additionally, soda blasting is effectively used for graffiti removal, cleaning masonry surfaces, and restoring historical buildings. Its gentle nature ensures that the underlying materials remain intact during the cleaning process.

Benefits of Soda Blasting

There are numerous benefits to using soda blasting as a cleaning method. Some of these include:

- Environmentally Friendly: Soda blasting uses non-toxic, biodegradable materials that do not harm the environment.

- Non-Abrasive: It cleans surfaces gently without causing damage or altering surface dimensions.

- Effective Deodorization: Sodium bicarbonate neutralizes odors, making it an excellent choice for fire damage restoration.

Choosing the Right Equipment

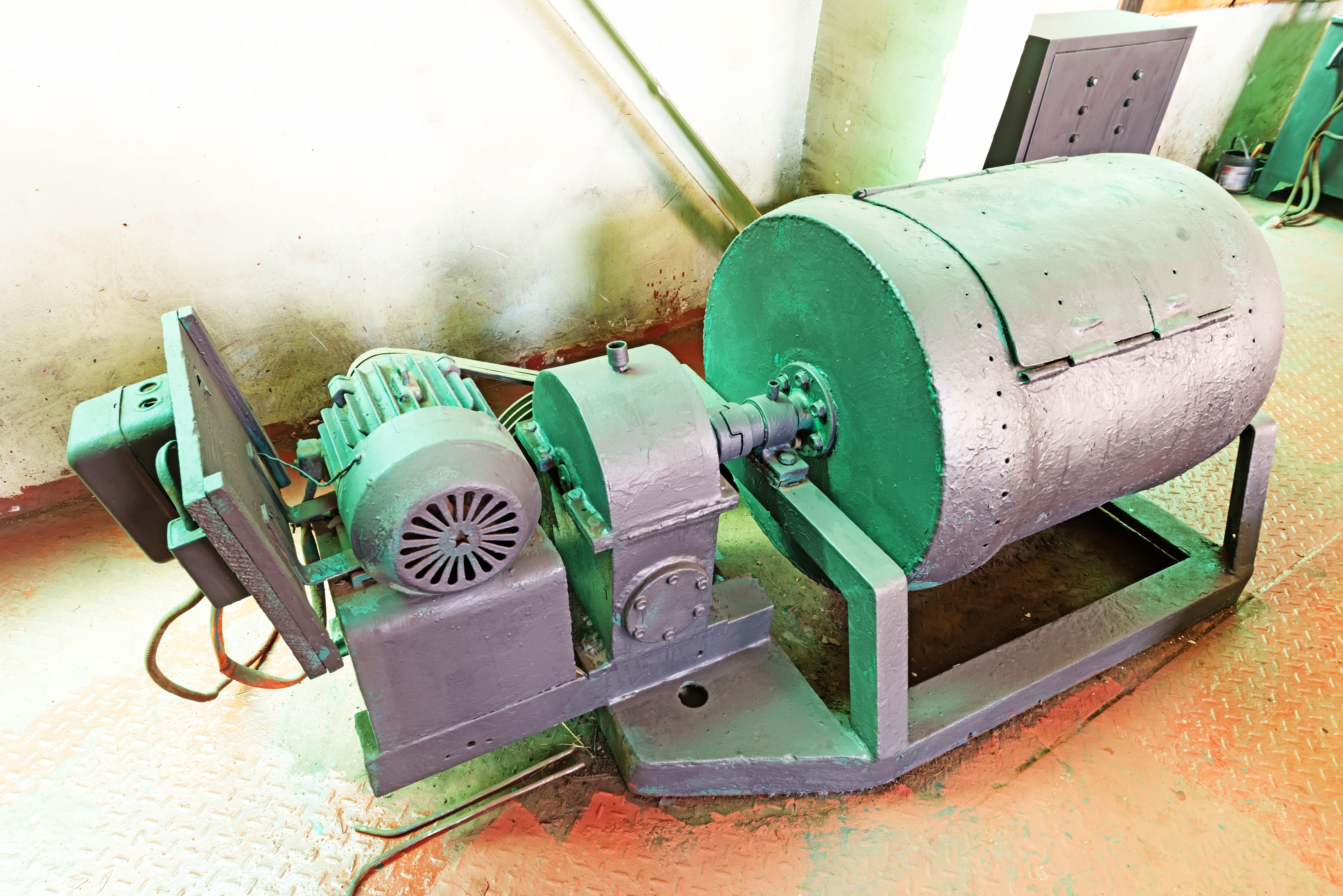

When considering soda blasting, it’s important to select the right equipment for your specific needs. Soda blasters come in various sizes and configurations, from portable units for small projects to larger systems for industrial applications. Selecting the right setup ensures efficiency and effectiveness in your cleaning or restoration tasks.

Additionally, consider the air compressor specifications required for optimal performance. Adequate pressure and airflow are crucial for achieving the best results in soda blasting operations.

Safety Considerations

While soda blasting is safer than many other methods, it still requires adherence to safety protocols. Operators should wear appropriate protective equipment, such as goggles and masks, to avoid inhaling dust or debris. Ensuring proper ventilation in the work area is also essential to maintain a safe environment.

Furthermore, understanding how to properly handle and dispose of spent materials is vital. Even though baking soda is non-toxic, the contaminants removed from surfaces may require careful disposal according to local environmental regulations.

Conclusion

Soda blasting offers an effective and safe alternative to traditional abrasive cleaning methods. Its versatility and numerous benefits make it an attractive option for various industries and applications. By understanding its working principles and applications, you can make informed decisions about using soda blasting for your cleaning or restoration needs.